Executive Summary

Manufacturing supply chains have grown increasingly complex, requiring resilience and agility to mitigate disruptions and meet customer demands. MuleSoft’s API-led integration offers a transformative solution by connecting disparate systems, breaking down data silos, and enabling real-time visibility across supply chain operations. However, challenges such as legacy systems, data silos, and change management can hinder successful implementation. By adopting a strategic, phased approach and leveraging MuleSoft’s robust tools, manufacturers can build agile, future-ready supply chains that reduce costs, improve efficiency, and enhance collaboration.

With MuleSoft experts like Neev Systems, manufacturers can ensure seamless implementation and ongoing support for their integration initiatives.

Key Takeaways

- Conduct a system assessment to identify gaps and prioritize integration efforts.

- Use MuleSoft’s pre-built connectors to accelerate implementation.

- Start with a pilot project before expanding across the supply chain.

- Upskill teams or collaborate with MuleSoft-certified experts.

- Implement strong change management to ensure adoption and success.

Is your supply chain prepared for the next disruption, or are you leaving success to chance?

In the global marketplace, manufacturers face increasing pressure to deliver goods faster, at lower costs, and with greater precision. Supply chains have become more complex than ever, often spanning multiple countries and involving numerous stakeholders. Amidst this complexity, disruptions such as pandemics, geopolitical tensions, or natural disasters can cause devastating ripple effects.

Supply chain resilience is no longer a nice-to-have but an absolute necessity. As manufacturers seek to safeguard operations, enhance efficiency, and meet growing customer demands, one solution stands out: MuleSoft’s API-led integration.

Every delay, inefficiency, and missed opportunity to adapt gives your peers a chance to gain a competitive advantage. MuleSoft’s API-led integration is helping manufacturers like yours unlock real-time data, streamline processes, and prepare for the future.

Discover how you can build an integrated, resilient supply chain that not only withstands disruption but thrives in the face of it.

Why Resilience Matters in Supply Chains

Supply chains are the backbone of manufacturing operations. They encompass everything from sourcing raw materials to delivering finished products. However, global interconnectedness makes supply chains highly susceptible to disruptions. A study by Statista reveals that the number of supply chain disruptions increased from 3700 in 2019 to 11,642 in 2021.

When disruptions occur, manufacturers risk losing revenue, damaging their reputation, and disappointing customers. The stakes are high:

- Missed delivery deadlines: Late shipments can lead to lost business opportunities and strained customer relationships.

- Increased operational costs: Disruptions often force manufacturers to source materials from alternative suppliers, usually at a higher price.

- Compliance Risks: Non-compliance with regulations due to supply chain inefficiencies can lead to hefty fines and legal repercussions.

What is API LED connectivity in MuleSoft?

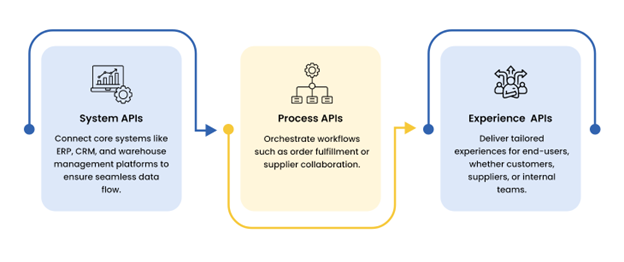

API-led connectivity in MuleSoft is an approach to system integration that organizes APIs into three reusable layers: System APIs to access core systems, Process APIs to handle business logic and data processing, and Experience APIs to deliver data to specific user interfaces or channels. This structured approach promotes API reuse and reduces reliance on point-to-point integrations, enabling faster development, improved scalability, and hassle-free system adaptability.

How can supply chain resilience be improved?

Building resilience requires visibility, agility, and the ability to act on data in real-time — capabilities that MuleSoft’s API-led connectivity inherently supports.

The State of Supply Chains Without the MuleSoft Advantage

Before advanced integration platforms like MuleSoft came into the picture, manufacturers struggled with several persistent challenges that hindered supply chain efficiency and resilience. These include:

How to Build an Integrated and Resilient Supply Chain

Creating an integrated and resilient supply chain involves a strategic approach that combines technology, processes, and collaboration. By implementing these steps, manufacturers can build a supply chain capable of withstanding disruptions and adapting to dynamic market conditions.

Map the supply chain

Start by mapping all supply chain processes, systems, and stakeholders to identify integration points and inefficiencies.

Standardize data

Implement data standardization across systems to ensure consistency and facilitate seamless data flow.

Leverage API-led connectivity

APIs can connect legacy systems, partners, and new applications, ensuring real-time data exchange and improved visibility.

Embrace automation

Automate key processes, such as inventory tracking, order fulfillment, and supplier collaboration, to reduce manual errors and improve efficiency.

Build redundancy

Incorporate backup systems and alternative workflows to maintain operations during disruptions.

Enhance visibility

Use integrated dashboards and analytics tools to monitor supply chain performance and proactively address issues.

Improve collaboration

Strengthen relationships with suppliers and partners by sharing real-time data and aligning objectives.

Adopt scalable solutions

Ensure your integration framework can adapt to changing business needs and market demands.

The Role of APIs in Supply Chains

APIs are the building blocks of modern digital ecosystems. They enable seamless communication between disparate systems, applications, and devices. In supply chains, APIs facilitate the flow of critical data, from inventory levels to shipping updates, across stakeholders in real time.

MuleSoft’s API-led approach goes a step further by providing a unified platform to connect, orchestrate, and manage these APIs.

MuleSoft proposes a new, modern approach to integration. Using a three-layered approach, MuleSoft ensures manufacturers can achieve end-to-end visibility, streamline operations, and swiftly respond to disruptions. Here’s how it works:

Build Resilient Supply Chain Integration

Why Supply Chain Needs API-led Connectivity

MuleSoft’s API-led integration delivers several benefits tailored to the unique needs of manufacturers:

Real-time visibility

Manufacturers need a clear view of their supply chain to identify bottlenecks and predict potential disruptions. API-led connectivity increases supply chain visibility and consolidates data from multiple sources, providing a single source of truth. It enables manufacturers to:

- Track shipments in real-time

- Monitor inventory levels across locations

- Predict delays using data analytics

Enhanced collaboration

Supply chains involve multiple stakeholders, including suppliers, logistics providers, and distributors. Miscommunication or delays in information sharing can lead to costly errors. MuleSoft simplifies collaboration by integrating systems and ensuring that all stakeholders have access to up-to-date information.

Scalability and flexibility

As manufacturers grow, their supply chains become more complex. MuleSoft’s platform is highly scalable, allowing businesses to integrate new systems, partners, or technologies without disrupting existing workflows.

Cost efficiency

Manual processes and redundant data handling lead to inefficiencies and higher costs. MuleSoft automates repetitive tasks, reduces errors, and eliminates the need for costly point-to-point integrations.

Faster decision-making

With access to real-time data, manufacturers can make informed decisions faster. Whether rerouting shipments due to a weather event or adjusting production schedules based on demand, MuleSoft enables agility at every step.

Challenges of Implementing MuleSoft in Supply Chains

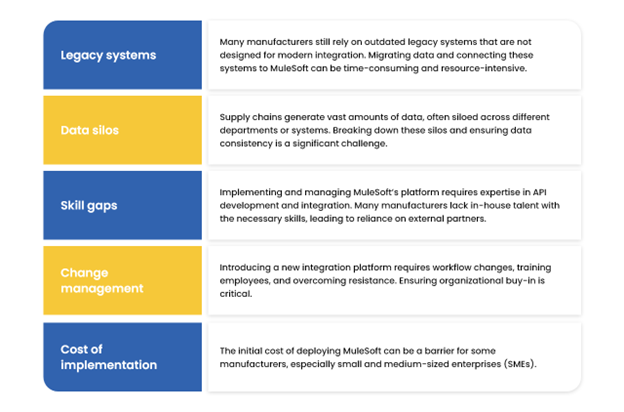

While the benefits of MuleSoft’s API-led integration are undeniable, implementing it in a manufacturing supply chain is not without challenges. These hurdles often stem from the complexity of supply chains and the need for organizational alignment. Here are the key challenges:

How to Mitigate Implementation Challenges

Implementing MuleSoft presents significant challenges, but they are not unbeatable. With the right strategies, manufacturers can overcome these hurdles and unlock the full potential of API-led integration. Now, what are the integration strategies for supply chain management?

1. Conduct a thorough assessment

Before implementation, conduct a comprehensive assessment of your existing systems, processes, and data architecture. Identify potential bottlenecks and develop a roadmap for integration.

2. Invest in training and upskilling

Equip your team with the skills needed to manage MuleSoft’s platform. This can include:

- Providing API development training for in-house IT teams.

- Partnering with MuleSoft-certified professionals for guidance.

3. Start small and scale gradually

Instead of a full-scale implementation, start with a pilot project focusing on a specific use case, such as integrating inventory management with order processing. Once successful, expand to other areas.

4. Use MuleSoft’s pre-built connectors

MuleSoft offers various pre-built connectors for popular systems like SAP, Oracle, and Salesforce. Using these connectors can significantly reduce implementation time and effort.

5. Engage external partners

If in-house expertise is limited, consider partnering with a trusted MuleSoft implementation partner. These experts can provide guidance, reduce implementation timelines, and ensure a smoother transition.

6. Focus on change management

Communicate the benefits of MuleSoft to all stakeholders and involve them in the implementation process. Provide training sessions, address concerns, and celebrate early wins to build momentum.

Boost Your Supply Chain Resilience with MuleSoft

Supply chain resilience is the cornerstone of sustainable manufacturing. MuleSoft’s API-led integration gives manufacturers the tools to build agile, efficient, and connected supply chains. While implementation challenges exist, they can be mitigated with a strategic approach, the right partnerships, and a commitment to change.

At Neev Systems, we specialize in turning these challenges into opportunities. Our certified MuleSoft experts curate customized solutions to align with your organization’s unique requirements and objectives. From consulting and implementation to custom connector development and ongoing support, we offer comprehensive services to simplify your IT architecture and reduce costs.

Create a connected enterprise with seamless and secure MuleSoft integration services. Start your journey with Neev Systems and transform your supply chain into a resilient, future-ready powerhouse today.

Make Your Supply Chain Resilient

Ansar Syed

With 10+ years of experience as an integration architect, Ansar specializes in delivering complex business solutions through strategic planning, custom designs, and process automation. He collaborates closely with stakeholders to enable seamless business processes and exceptional outcomes using integration tools.